MSR165 Data Logger Vibration, Shock, Acceleration ±15 g or ±200 g • Recording time up to 5 Years • Stores over 2 m or 1 bn (SDcard) Readings • add. Sensors for Temperature, Humidity, Pressure, Light

MSR165 data logger for shocks, vibration, jolts · 3-axis-acceleration sensor ±15 g or ±200 g · MSR ShockViewer software

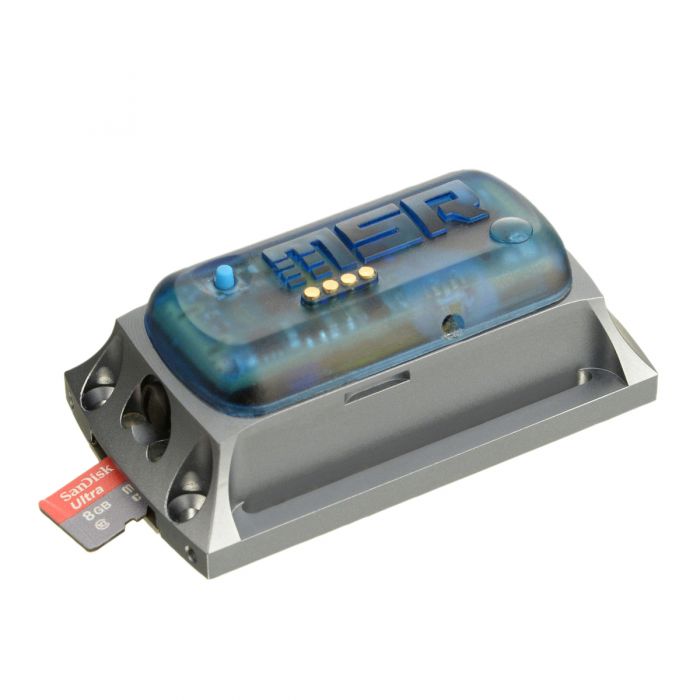

Our best-selling data logger for shock and vibration measurements! With its measurement frequency of 1600/s, high-capacity memory and low power requirements, the msr165 is ideal for transportation monitoring, fault diagnoses and load tests. Many options available such as additional sensors, analogue inputs or a slot for a microSD card.

Product features Vibration and Shock Data Logger MSR165

- High-performance shock and vibration data logger with internal or external 3-axis-acceleration sensor ±15 g or ±200 g

- Measuring/storage rate of the acceleration sensor: 1600/s to every 12 h (±15 %)

- Measuring/storage rate adjustable between 25 Hz and 1600 Hz

- Continuous data recording for vibration measurements

- 32 measured values are recorded even before the shock event takes place

- Up to 4 additional sensors for temperature, humidity, air pressure, 4 analogue inputs also available (see Configurator)

- Stores up to 2 million (internal memory) or 1 billion (microSD Card) total readings

- Recording time of up to 5 years, depending on the battery and the measurement rate

- Small in size, rugged anodised aluminium case, PC

- Free MSR PC software MSR Setup, Reader, Viewer and Online software

- Free MSR ShockViewer analysis software for extensive analysis and graphical representation of the data recorded

Product information:

MSR165 with ±15 g or ±200 g 3-axis accelerometer.

The MSR165 data logger is available with an internal ±15 g or ±200 g acceleration sensor. The ±15 g acceleration sensor proves to be very suitable for measuring light shocks and vibrations, for example when shipping parcels or pallets. Shock values up to ±15 g can be recorded with a measuring rate of up to 1'600 measurements per second over the entire measuring period.

With the ±200 g acceleration sensor, strong shocks and impacts can be recorded. A measuring range of ±200 g is required when very large forces suddenly occur. This can be the case in transport monitoring, for example, but also in aerospace applications or drop and impact tests in industry.

Select the desired acceleration sensor in the configurator tab!

MSR165 with microSD card: Large memory for large amounts of data

When measuring continuously at high rates, this generates very large amounts of data, which can quickly exhaust conventional memory. The MSR165 data logger can therefore be ordered with a slot for a microSD card. The microSD card increases the logger's storage capacity from 2 million readings to over 1 billion readings. The acceleration data logger is ideal for long-term recordings, not least thanks to its extremely low power consumption.

MSR ShockViewer software for analysis

After recording, the shock and vibration data from your logger can be transferred to a computer via USB and evaluated. The scope of delivery of the MSR165 includes the MSR PC software for configuring and evaluating the data as well as the MSR ShockViewer evaluation software. With the MSR ShockViewer, extensive measurement data can be clearly displayed, shock events can be quickly analysed and conclusively documented.

You need more advice? Contact us!

Technical data of the sensors, housings and batteries

Technical details can be found on the Configurator tab.

General technical data of the Vibration and Shock Data Logger MSR165

| Memory capacity: | Over 2 million measurement values, with microSD card over 1 billion. |

| Push-button: |

Set bookmark or start and stop recording. |

|

LED:

|

Blue: Record indicator |

|

Power supply: |

Lithium-polymer battery (1000 mAh), rechargeable via USB port, recording period up to 6 months or replaceable batteries (Li-SOCl2, 3.6 V, 2 x 7700 mAh), for recordings up to 5 years. |

| Interface: |

USB |

| PC software: |

MSR PC Software (standard), MSR ShockViewer analysis software System requirements: Windows 7 or higher, USB port. |

| Operation conditions: |

Temperature: -20...+65 °C |

| Storage conditions: |

Temperature: +5...+45 °C (ideal storage conditions for the battery) Humidity: 10...95 % relative humidity, non-condensing |

| Standards: |

The MSR165 complies with EU-Directives RoHS/WEEE. |

Software

Our software is scanned for viruses with Microsoft Defender.

- MSR pc software (standard) (2023-05-25, v6.09.01, MD5: fd6360125328dd1707688238095543b3)

- MSR165 ShockViewer (2022-10-12, v1.02.28, MD5: 2cf6705f75439e8c28dc7a2155827297)

- MSR165 firmware update (2023-06-15, v2.40, MD5: eadaaa93e8bc365cfd24bab957153f09)

Instruction manuals

- MSR165 brief instructions (2019-08-23)

- MSR165 user manual (v5.04)

- SD Card user manual

- Strap and screw fastening for MSR165

- Mounting instructions for shock and vibration data loggers

- MSR ShockViewer video tutorials

Datasheets

- Datasheet data logger MSR165

- Dimension sheet MSR165B8

- Dimension sheet MSR165B52

- Dimension sheet external acceleration sensor

- Datasheet analogue inputs type 3

Certificates

- Air Cargo Approved Tracking Devices MSR: Lufthansa, Austrian, SWISS, Brussels Airlines, Customer Owned Tracker Guideline

- RTCA DO-160G ENVIRONMENTAL CONDITIONS AND TEST PROCEDURES FOR AIRBORNE EQUIPMENT SECTION 21, Cat. H

- UN38.3 Certificate for Lithium Polymer 1000 mAh

- Certificate Saft LS 26500 (.zip 1.64 MB)

FAQ – frequently asked questions about MSR data loggers

Where is the MSR165 vibration and shock data logger used?

Small format, large memory, high measuring rate, low power consumption: these features predestine the MSR165 for applications in a wide range of industrial sectors.

For example, the MSR165 can be used to determine the optimal utilisation of expensive production machines and thus increase their service life. By monitoring the vibrations of servo axes or measuring vibrations on tool turrets of production machines, the user can, for example, draw conclusions about whether a machine is overloaded, the drive is not running optimally, service is necessary or how strongly the vibrations are transmitted to the machine.

In the transport industry, the MSR165 is often used to record and document vibrations, jolts, shocks and impacts that affect goods during transport. The data obtained can be used to minimise transport risks and optimise packaging.

Further application examples for the MSR165: measurements of shocks on vehicles, load tests, vibrations on buildings, vibration measurements on cooling machines, vibration measurements on wind turbines and much more.

User reports on the MSR165 can be found on the website of the manufacturer MSR Electronics GmbH:

- Fresenius Medical Care: MSR165 data logger for machine, workpiece and production optimisation

- u-blox: MSR165 data logger for investigating vibration influence

- Stadler Rail: Use of MSR165 data logger for measurements on ride comfort and safety

- Acceleration data logger MSR165 for fault diagnosis of defective sensor

- Talos Packaging Systems (UK): MSR165 Data Logger to measure g-forces

- Fraunhofer Institute for Manufacturing Engineering and Automation (IPA): The acceleration data logger MSR165 monitors process dynamics during the machining of CFRP parts.

- Travelling in space: MSR165 Data Loggers on the way to the International Space Station ISS)